I got a request to post details of our all-grain setup here. Unfortunately, it’s in another state, but I’m slowly rebuilding it–better.

Our system was a recirculating mash system (RMS) with fairly precise temperature control. The temperatures were controlled via a python code written by Trevor, which took input from strategically placed thermocouples and activated hot water heater elements as necessary. This allowed us to very easily control our mash temperatures, giving us an enormous amount of control on the final flavors.

All-grain brew tutorial

For those who are familiar with all grain brewing, skip this section. For the rest, here is a short and basic tutorial on all grain brewing. All grain means you get all of your fermentable sugars from grain, rather than adding some kind of malt extract.

Basically, you need to ‘mash’ your grain at a particular temperature and water content to optimally activate the enzymes that convert starch into fermentable sugar. By controlling the temperature, you can activate/deactivate (or even denature) particular groups of enzymes (alpha amylase being the primary one) to control how ‘sweet’ or ‘dry’ the beer will be. Temperature and timing is everything. Generally the mash is somewhere in the neighborhood of 150-160 degrees Farenheit.

At the end of the mash, the ‘wort’ (pronounced wert, like Bert in Bert and Ernie) is sent to the boil, where it is heated to boiling and hops are added. After some period of time (generally something like an hour), the wort is cooled, transferred to a sterile vessel, yeast is added, and the yeasties are left to work their magic.

Recirculating Mash System

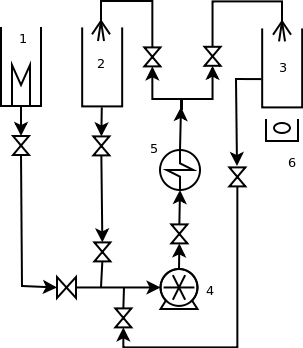

Recirculating mash system. (1) Hot Liquor Tank. (2) Mash Tun. (3) Boil kettle. (4) Pump. (5) Heat Exchanger. (6) Burner.

Our system produced between 10 and 12 gallons of beer per batch, requiring about 25 pounds of grain and a half pound of hops (depending on the recipe, of course). Our hot liquor tank (which just holds hot water), consisted of a keg with the top cut off, a valve installed in the bottom, and a thermocouple installed on the inside which controlled a stainless steel hot water heater element installed in the bottom (Figure 1, element 1).

A pump (4) would drain the tank into the Mash Tun (that which holds the grain for the mash), which was also a keg with a false bottom and valve assembly installed (2). The hot water would flow through a heat-exchanger (5), which was a water-filled vessel (an old soda keg) controlled by another hot water heater element. The water or wort being pumped through was contained in a coil, and the temperature of the exiting liquid was read by a thermocouple which controlled the temperature of the heat exchanger. The wort would be continuously circulated, keeping the temperature constant, for at whatever temperature and whatever time the recipe called for.

At the end of the mash, the wort would be pumped into the boil (3), which was another keg heated by a turkey fryer propane burner (6). This burner could go to 11, so we had to make sure to bring the wort to a boil slowly to avoid pyrolysis or caramelization. At this point we added hops and whatnot, and during the boil would replace the hot water in the heat exchanger with cold water.

At the end of the boil, we would run some boiling wort through the system to make sure it all was sanitary, then cool the boil using the heat exchanger. Pump into carboys, pitch the yeast, and go home.

The python interface controlling the temperatures was key. We could make a very clear beer just spot on whatever recipe we designed. Aside from having to take it apart to clean it every time, it was so much easier than stovetop.